JHY PCB Blog Hub

Your Source for Expert PCB Design, Manufacturing, and Assembly Insights – Stay Informed with 2025 Trends!

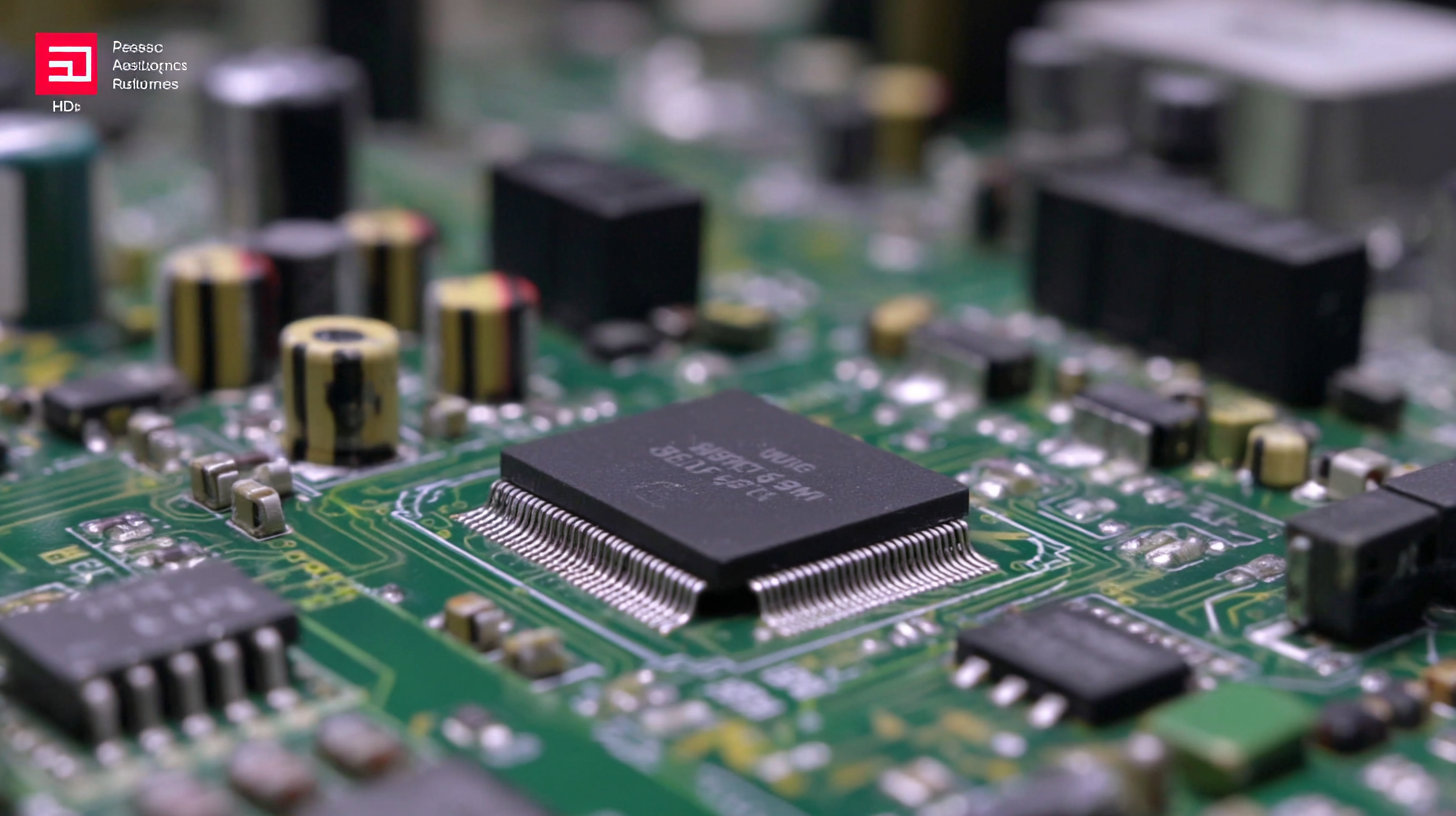

Solutions for Efficient Best Printed Board Assembly Manufacturing

In an increasingly competitive global marketplace, the ability to produce high-quality Printed Board Assembly (PBA) has become a critical differentiator for manufacturers seeking to expand their reach from China to the world. According to a recent report by the IPC, the global electronics manufacturing services market is projected to reach $728 billion by 2026, with a significant portion driven by advancements in PBA technologies. As the demand for complex electronic devices rises, manufacturers are challenged to enhance efficiency while maintaining stringent quality standards. By adopting innovative manufacturing solutions and streamlining processes, companies can not only improve their operational performance but also meet the evolving expectations of consumers worldwide. Effective PBA manufacturing plays a pivotal role in this transformation, positioning businesses to capitalize on the growing demand for sophisticated electronics in various sectors, including automotive, healthcare, and consumer electronics.

Understanding Industry Standards in PCB Assembly Manufacturing

Understanding industry standards in PCB assembly manufacturing is crucial for delivering high-quality printed circuit boards (PCBs) that meet customer expectations. The IPC (Institute of Printed Circuits) establishes various standards, like IPC-A-610, which outlines the acceptability of electronic assemblies. Familiarizing yourself with these standards can significantly improve the reliability and performance of PCB products.

Tip: Always keep a copy of relevant IPC standards on hand during design and assembly to ensure compliance from the start.

In addition to IPC guidelines, it’s important to consider other regulatory standards such as ISO and RoHS. These frameworks ensure good manufacturing practices and environmental responsibility. Companies can enhance their reputation and marketability by adhering to international standards, which are increasingly becoming a requirement in global trade.

Tip: Conduct regular training sessions for your assembly team on these standards to ensure everyone is on the same page and to minimize errors in the assembly process.

Key Techniques for Streamlining the PCB Assembly Process

In the fast-evolving world of electronics, streamlining the PCB assembly process is essential for manufacturers aiming for efficiency and cost-effectiveness. According to the IPC's "Statistical Program for the PCB Industry," the average assembly time decreased by about 20% over the past five years due to advancements in automation and production techniques. Emphasizing automation, manufacturers can implement pick-and-place machines that enhance precision and speed, thus reducing assembly time significantly.

In the fast-evolving world of electronics, streamlining the PCB assembly process is essential for manufacturers aiming for efficiency and cost-effectiveness. According to the IPC's "Statistical Program for the PCB Industry," the average assembly time decreased by about 20% over the past five years due to advancements in automation and production techniques. Emphasizing automation, manufacturers can implement pick-and-place machines that enhance precision and speed, thus reducing assembly time significantly.

Tip: Invest in advanced inspection technologies such as automated optical inspection (AOI) systems to mitigate errors and minimize rework costs, which can account for up to 30% of total production costs, as highlighted in a recent industry report by the NPI (New Product Introduction) Research Group.

Another key technique is optimizing the supply chain for critical components. Studies show that companies with streamlined supply chains achieved a 25% faster time-to-market, demonstrating the competitive edge gained through efficiency. Additionally, employing concurrent engineering practices aids in early detection of design flaws, further expediting the assembly process.

Tip: Establish close relationships with component suppliers to ensure timely deliveries and to adhere to production schedules effectively, safeguarding your assembly line from potential delays. By integrating these key techniques, PCB manufacturers can not only enhance their production capabilities but also improve overall profitability.

Best Practices for Quality Control in PCB Production

In the fast-evolving landscape of printed circuit board (PCB) manufacturing, quality control plays a pivotal role in ensuring efficient production processes and superior product reliability. According to recent market insights, the PCB industry is projected to reach a staggering value of $75.9 billion by 2024, with forecasts predicting an increase to $110.9 billion by 2033, demonstrating a compound annual growth rate of 4.3%. This surge highlights the growing demand for innovative manufacturing techniques that emphasize quality throughout the production lifecycle.

Implementing best practices in quality control within PCB production is essential. The integration of artificial intelligence in engineering has dramatically enhanced manufacturing efficiency, allowing engineers to create standardized operating procedures in mere seconds. Additionally, agile development techniques have reduced design turnaround times from seven days to merely twelve hours. Such advancements not only streamline the manufacturing process but also minimize the potential for defects, ensuring that the final products meet the rigorous standards of the electronics industry. As PCB technology becomes increasingly crucial to virtually all electronic devices, maintaining high-quality standards will be integral to meeting market demands and enhancing overall product performance.

Innovative Technologies Enhancing PCB Assembly Efficiency

In the rapidly evolving landscape of printed circuit board (PCB) assembly, innovative technologies are pivotal in enhancing manufacturing efficiency. According to a report by the IPC, there has been a notable increase in automation adoption among PCB manufacturers, with over 65% incorporating advanced robotics and automation tools into their production lines. This shift not only streamlines assembly processes but also significantly reduces the likelihood of human error, thereby improving overall yield rates.

Furthermore, the integration of IoT (Internet of Things) in PCB assembly is transforming traditional methods. A study by MarketsandMarkets projects that the IoT in manufacturing market will reach $1.3 trillion by 2026, driven largely by the need for real-time data analytics and monitoring. Implementing smart sensors in assembly lines allows for predictive maintenance and enhanced tracking of operational workflows, leading to a potential 15% reduction in manufacturing downtime. As manufacturers continue to embrace these cutting-edge technologies, the focus remains on delivering high-quality PCBs while maximizing efficiency and cost-effectiveness.

Innovative Technologies Enhancing PCB Assembly Efficiency

Cost-Effective Strategies for Optimizing PCB Manufacturing Practices

In the competitive landscape of PCB manufacturing, adopting cost-effective strategies is essential for optimizing production practices. According to a report by IPC, an estimated 30% of the total manufacturing costs in PCB assembly is attributed to wasted efforts, materials, and time. Streamlining processes can lead to significant savings. Implementing lean manufacturing techniques, such as just-in-time inventory systems, can drastically reduce storage costs and minimize waste. Furthermore, investing in high-quality automation can ensure precision while reducing labor costs, resulting in a more efficient production line.

Tip: Regularly review your supplier relationships to negotiate better prices and terms. Collaborating with suppliers can lead to bulk purchase discounts and improved material quality, significantly impacting overall production costs.

Another cost-effective strategy is adopting advanced technology in design stages. With the rapid progression of design software, manufacturers can simulate and test PCBs virtually. A recent study revealed that integrating simulation tools can reduce design errors by 50%, leading to fewer costly reworks and shorter time-to-market. Embracing these technologies allows for better resource allocation and increased production efficiency.

Tip: Conduct regular training for your engineering teams on the latest design software to maximize the benefits of technology, ultimately enhancing productivity and reducing costs.